Description

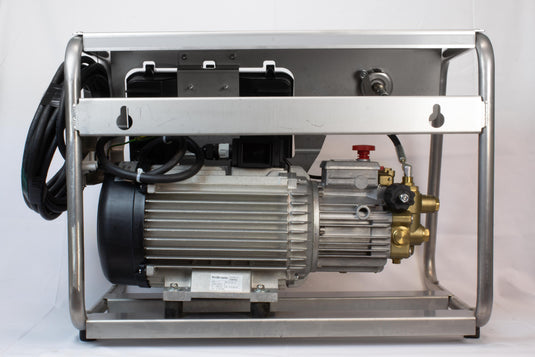

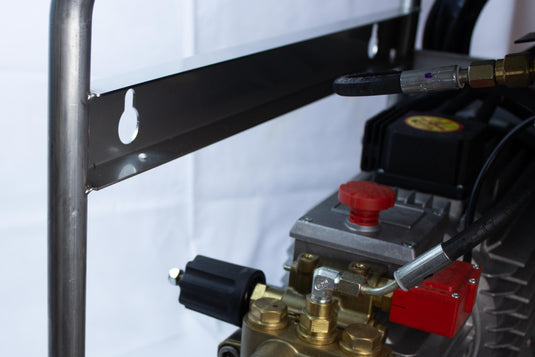

KWS-series can be wall-mounted or used as a stationary unit. Made in Germany.

Discover the unparalleled resilience and superior performance that set Kranzle's KWS series pressure washers apart in the industrial and commercial sectors. Engineered with German precision, these machines epitomize the fusion of top-grade materials and avant-garde technology, setting a new benchmark for durability and efficiency in professional cleaning. Unlike the competition, which often cuts corners on quality, leading to frequent breakdowns and replacements, Kranzle represents a bastion of reliability and steadfast performance.

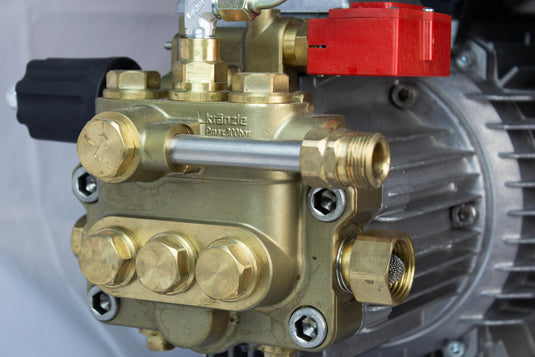

The KWS series, with its cold water stationary electric pressure washers delivering 2400 PSI and up to 5.0 gallons per minute, is specifically designed for rigorous daily use. Whether it's for a factory, food processing plant, or vehicle wash bay, its professional-grade accessories and Kränzle AQ pump, powered by a robust Kranzle electric motor available in 220V or 440V, ensure optimal cleaning for any heavy-duty task. Unique to Kranzle, the pump boasts the ability to run dry and on bypass for extended periods without damage – a testament to its superior durability, confirmed by independent lab tests.

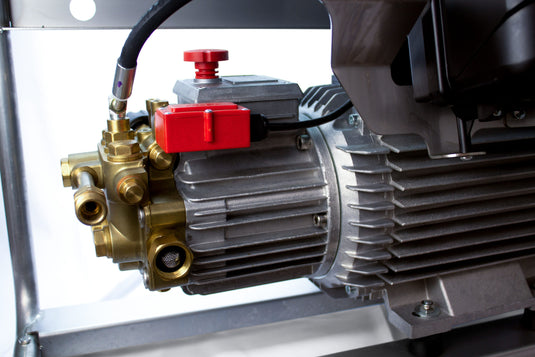

Each KWS unit is equipped with the Total-Stop feature, an innovation that shuts down the pressure washer when the trigger is released, minimizing wear on the pump and conserving energy. This not only extends the machine's lifespan but also underscores Kranzle's commitment to sustainable operation. The inclusion of a professional gun-jet lance, wire braided hose, and fan spray nozzle, among other high-quality accessories, ensures a seamless and effective cleaning experience, free from the frustrations of inferior products.

Kranzle's dedication to excellence is evident in every aspect of the KWS series—from the new style stainless steel frame that enhances portability and accessibility to the auto on/off gun-jet that simplifies operation. This series is not just a tool but a reliable partner in maintaining cleanliness and hygiene in demanding industrial environments.

Choose Kranzle for your cleaning needs and invest in a solution that promises not just to meet but exceed expectations with every use. Say goodbye to the cycle of buying and replacing inferior machines and embrace the assurance of lasting performance and efficiency that comes with every Kranzle pressure washer. Your investment in quality reflects the value you place on excellence and sustainability in your professional cleaning tasks.

Features

- Advanced Kränzle pump design gives multi-hour bypass and run-dry capability preventing accidental pump damage

- Stainless steel frame for mounting on a wall or shelf

- Auto on/off control at gun jet with a 30-90 second variable time delay reduces wear and tear on the pump

- 33-feet wire braided hose with safety couplers

- TEFC 1600 RPM electric 220V - 440V,17A-23A, single or 3 phase motor

Specifications

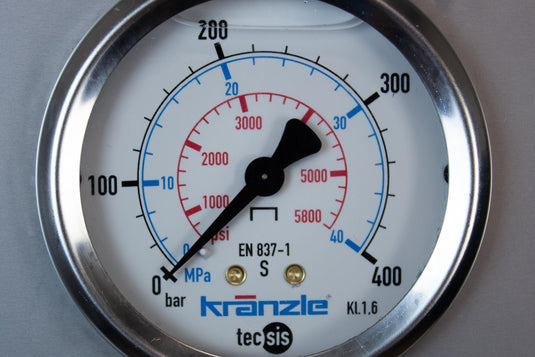

- Operating press. fully adjustable: 450-2400 psi (30-165 bar)

- Nozzle size: 045

- Permissible overpressure: 2600 psi (180 bar)

- Water output: 3.3 Gpm at 1700 rpm max.

- Maximum water inlet pressure: 145 psi (10 bar)

- Water inlet temperature: 140 °F (60 °C)

- Hose drum: no

- Steel braided high-pressure hose: 10 m

- Total stop system (TS): yes

- Connected load: 220-230~1 V, 60 Hz, 23 A

- Power input: P 1 - 5.5 kW

- Power output: P 2 - 5.0 HP (3.7 kW)

- Weight: 62 kg

- Dim. in mm: 675 x 440 x 520

- Acoustic level acc. to DIN 45 635: 89 dB (A)

- Acoustic power LWA: 91 dB (A)

- Recoil at lance: approx. 25 N

- Vibration at lance: 2,2 m/s2

Warranty

1-year commercial

Manuals

Kranzle New Owner Tips

1. Oil Life

Expect approximately 50 hours of oil life with regular usage.

If using the equipment once a week, oil should last roughly a year.

2. Built-In Hose Reel Units

Run these units lying down to ensure optimal heat management and oil flow.

3. Solid Brass Pump Housing

Key to machine longevity.

Offers excellent resistance to freezing.

4. Winter Storage Tips

In colder climates, ensure the pump is dry before winter storage.

Disconnect the water intake line and run the pump dry for 10 seconds to purge water.

5. Unloader Valve Usage

The unloader valve can adjust pressure but will also impact flow.

For car washing, it's advisable to leave the valve untouched.

6. Foam Cannon Circuitry

If using a foam cannon, consider a dedicated 20-amp circuit to ensure optimal performance.

7. Gauge Air Bubbles

Air bubbles in the gauge are normal.

Glycerin is used inside the gauge to minimize vibration.